I Cos'è la pompa di fuoco CB10/40

La pompa antincendio CB10/40 è una pompa dell'acqua centrifuga a singolo stadio dotata di un dispositivo di innesco a due pistone Quando la pompa funziona, il dispositivo di innesco viene automaticamente coinvolto e si disinnesta automaticamente una volta raggiunta la pressione richiesta Questa pompa antincendio presenta prestazioni eccellenti, struttura compatta, funzionamento semplice e manutenzione comoda, rendendolo adatto a varie applicazioni di camion dei pompieri

CB10/40 Specifiche della pompa antincendio:

| Modello | Condizione di lavoro | Fluire (L/S) | Pressione di uscita (MPA) | Velocità nominale (r/min) | Potenza dell'albero (KW) | Profondità di aspirazione (M) |

| CB10/40-xz | 1 | 40 | 1. 0 | 3135±50 | 60 | 3 |

| 2 | 28 | 1. 3 | 3390±50 | 61 | 3 | |

| 3 | 20 | 1. 0 | 3010±50 | 39 | 7 |

Ii Passaggi di installazione per la pompa antincendio CB10/40

1 Preparazione prima dell'installazione

Prima di installare la pompa antincendio CB10/40, confermare che il motore del motore e del telaio del camion dei pompieri sono compatibili con esso e preparare gli strumenti di installazione e i pezzi di ricambio necessari Inoltre, assicurarsi che l'area di installazione sia pulita e ordinata per facilitare le successive passaggi operativi

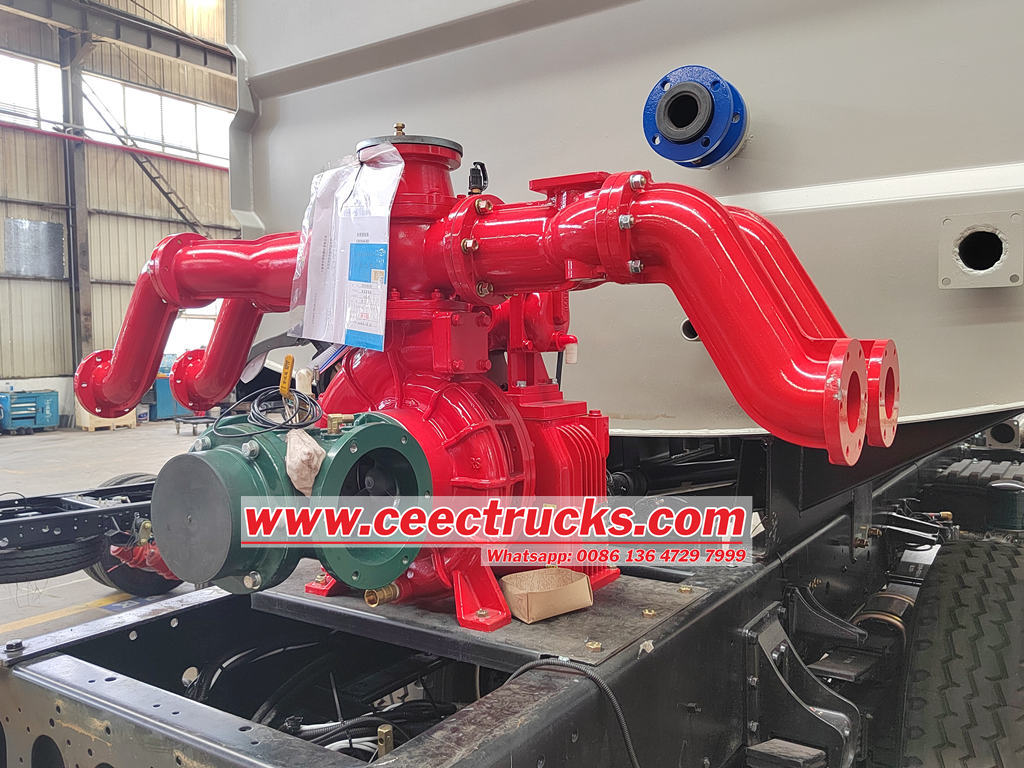

2 Installazione del dispositivo di innesco

Innanzitutto, correggi il dispositivo di innesco a due pistone nella posizione designata sul corpo della pompa Presta attenzione all'accurata connessione del sensore di separazione di innesco e dell'interruttore a pressione per assicurarsi che normalmente possano percepire e cambiare quando il corpo della pompa ruota

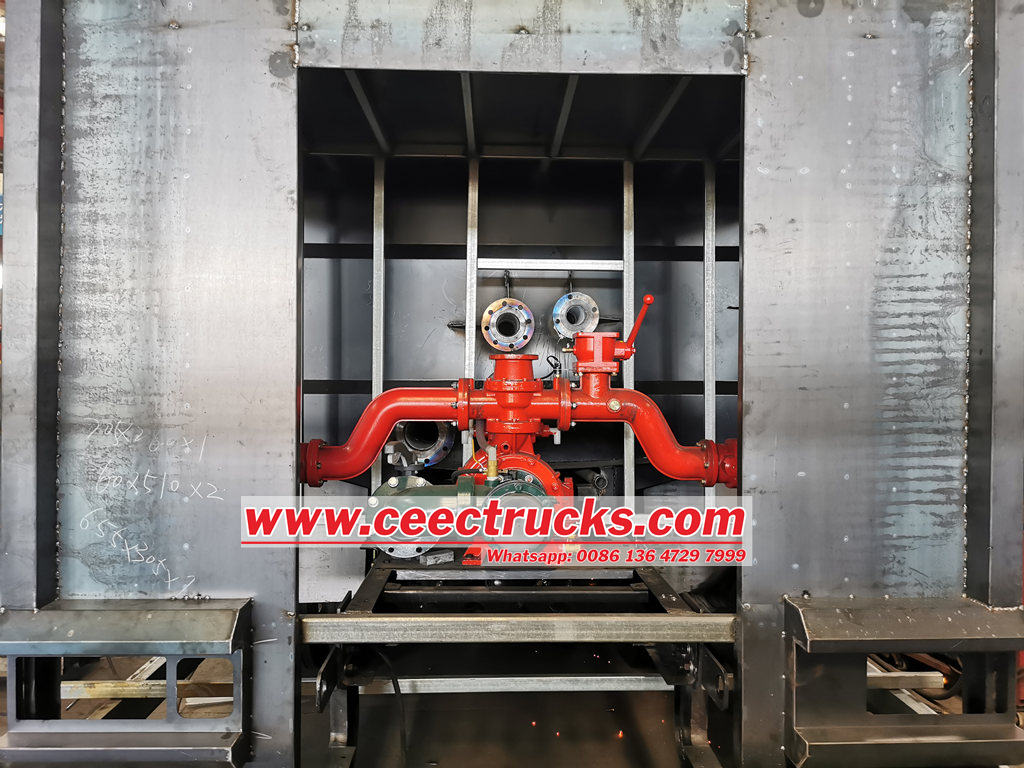

3 Fissaggio del corpo della pompa

Montare in modo sicuro il corpo della pompa sul telaio del camion dei pompieri usando bulloni e noci Assicurarsi che il corpo della pompa sia a livello per evitare vibrazioni e rumore durante il funzionamento

4 Collegamento dei tubi di ingresso e uscita

Collegare il tubo di ingresso e il tubo di uscita alle porte di ingresso e uscita del corpo della pompa, rispettivamente Durante questo processo, utilizzare il materiale di tenuta per prevenire le perdite d'acqua e assicurarsi che i tubi siano collegati in modo sicuro per evitare l'allentamento o la caduta durante la guida e il funzionamento

5 Collegamento del sistema elettrico

Collegare il sistema elettrico del corpo della pompa al sistema di alimentazione del camion dei pompieri per garantire che il motore della pompa possa avviarsi e funzionare normalmente Allo stesso tempo, collegare i circuiti di controllo per garantire che i componenti funzionali della pompa (come la valvola di ritegno e l'interruttore d'acqua residuo) possano rispondere accuratamente ai segnali di controllo

6 Ispezione e messa in servizio

Dopo aver completato le fasi di installazione di cui sopra, condurre un'ispezione completa per confermare che tutti i componenti sono installati in modo sicuro, i tubi sono strettamente sigillati e il sistema elettrico è correttamente collegato Quindi, eseguire una messa in servizio iniziale per confermare che la pompa antincendio CB10/40 può funzionare normalmente, il dispositivo di innesco funziona correttamente e il flusso e la pressione soddisfano i requisiti di progettazione

Iii Manutenzione di routine per camion dei pompieri CB10/40

Per garantire la durata a lungo termine e l'affidabilità della pompa antincendio CB10/40-xz, la manutenzione di routine e le cure sono essenziali I seguenti sono i punti chiave per la manutenzione:

1 Ispezione regolare:

Eseguire un'ispezione regolare almeno una volta alla settimana, incluso il controllo della tenuta di tutte le parti di connessione e garantire che non vi siano perdite

2 Lubrificazione:

Rifalisci l'olio lubrificante ogni 200 ore di funzionamento Controllare regolarmente il livello dell'olio per assicurarsi che si trovi nell'intervallo del livello dell'olio

3 Prevenzione della pulizia e della corrosione:

Mantieni pulita la superficie del corpo della pompa per prevenire la ruggine Durante lo stoccaggio e l'uso, assicurarsi che l'ambiente sia asciutto e ventilato per evitare di esporre il corpo della pompa in un ambiente umido per lunghi periodi

4 Test funzionali:

Condurre un test funzionale una volta al mese, incluso il test della pressione di flusso e uscita, per garantire che i parametri della pompa rientrino nell'intervallo di progettazione

5 Sostituzione di parti indossabili:

Se le parti indossabili come le guarnizioni delle guarnizioni e l'olio lubrificante mostrano segni di usura o invecchiamento, dovrebbero essere sostituite prontamente

Attraverso una corretta installazione, manutenzione di routine e funzionamento, la pompa antincendio CB10/40-xz può essere garantita per funzionare in modo affidabile in situazioni di emergenza, fornendo un forte supporto per gli sforzi antincendio.